The Pros and Cons of Vendor Managed Inventory

Time to read: 6 minutes

Consumer expectations for product availability have increased as omnichannel shopping has become more popular. Items must always be in stock for customers, regardless of where or how they purchase them. Your business could lose profits if a product is out of stock. Customers will go to a competitor instead. Online merchants need to coordinate with retailers, distributors, and suppliers if they want to remain competitive.

To build a lean, demand-driven supply chain, vendor-managed inventory (VMI) allows supply chain partners to communicate inventory data automatically. VMI enables you to increase in-stock rates, optimize shipments, and provide better forecasts. Additionally, you can easily adjust to any real-time changes in market demand.

VMI is fundamentally a supply chain agreement. It allows a manufacturer or supplier to decide how to manage the inventory for the merchant or sale. Large retail corporations like Amazon and Walmart commonly use this. It is advantageous for them since they work with many third-party merchants. In terms of supply, this indicates that the upstream agent is responsible for providing the downstream agent’s inventory. This type of business agreement is also known as managed inventory, continuous replenishment program, or supplier-assisted inventory replenishment.

How Vendor Managed Inventory Works

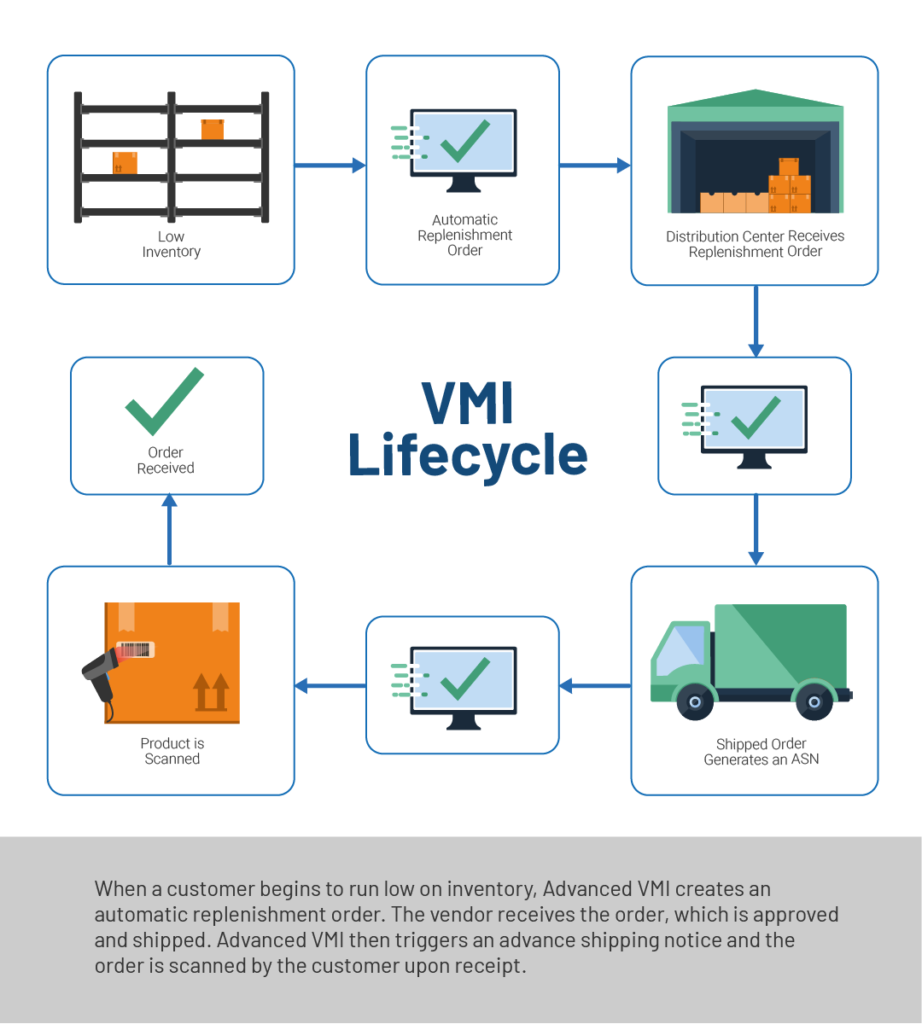

Vendor managed inventory refers to a set of procedures and inventory control software. With these tools, a manufacturer who is also a supplier assumes control of a distributor’s inventory stock optimization.

It is a B2B approach that strengthens the interaction and collaboration between suppliers and distributors, assisting both parties in coordinating their goals for efficient operations.

In a conventional company model, inventory volume and order timing are determined by product buyers. In a vendor managed inventory model, the supplier assumes this duty instead of the customer.

A vendor can maintain and replenish inventory at the client’s location and the customer’s specified quantities. Customers essentially contribute crucial data, typically via electronic data interchange (EDI). Inputs such as point of sale, current inventory levels, goal inventory levels, and forecasting insights are used to create a thorough and unique distribution strategy. Additionally, pre-established factors like service levels, inventory turn targets, and minimum and maximum shelf presence are also considered.

Businesses using VMI can benefit from shorter lead times, better transportation planning, enhanced customer experiences, and other benefits by implementing a VMI system.

Here’s a simple breakdown of the vendor managed inventory process:

- The goals and metrics that determine success for a VMI partnership are set by both the vendor and the buyer. Transaction costs, inventory turnover rate, and in-stock performance are common KPIs. The agreement will also specify whether the buyer will pay for the inventory when purchased or sold to the end user. Both parties must also agree on how returned surplus stock will be handled.

- The vendor ships inventory to the shipper or customer.

- The vendor monitors sales patterns and inventory levels of the products a buyer or retailer keeps stock of.

- The vendor determines when to place new orders and refill inventory based on demand predictions and lead time.

- The replenishment orders are placed when the vendor’s VMI specialist or planner reviews the calculations.

Challenges and Limitations for Vendor Managed Inventory

Like any other company model, vendor managed inventory doesn’t come without risks. The major drawback of VMI is that online merchants have to cede some level of control to a vendor or distributor. This is necessary to turn over the inventory management responsibility to another party.

Online businesses may find it difficult to agree with this since it requires high trust in the distributor or supplier. On the other hand, the vendor must be able to handle the obligations that a VMI agreement entails. Signing a VMI contract with an experienced service partner with a successful track record is important.

Poor Understanding of Data

A vendor must understand your inventory data; otherwise, the entire system could fall apart quickly. Successful VMI depends on a vendor’s capacity to assess data from the store and determine when to order additional inventory. This responsibility lies with the vendor. But when choosing a partner for VMI, the retailer should consider the vendor’s data expertise.

Sudden Inventory Changes

Anytime a retailer decides to start introducing new products or removing old ones, clear communication with the vendor is essential.

Introducing new products can be challenging because there is no data on those items for the vendor to forecast. This means the business must constantly contact the vendor to inform them how well the new product is selling.

Similarly, if a product is being phased out, the vendor needs to be informed so they don’t continue to order extra stock. Holding onto old or excess inventory can be costly and takes up valuable storage space.

Data Privacy and Security Risks

Any time you disclose your data with a third party, including through VMI partnerships, you put your company at risk. Make sure you have an in-depth confidentiality agreement.

Limited Partnership Agreements

Choosing a VMI partner and being unhappy with their service could disrupt the supply chain. If you find a more affordable or superior offering from other suppliers, being in a VMI arrangement might deter making the switch.

Ending a relationship can be quite difficult if it isn’t working out. Two organizations integrating is the basis of a VMI connection. Disengaging and leaving with that level of integration takes a lot of work.

Five Ways Vendor Managed Inventory Makes a Difference

VMI modifies the conventional ordering procedure by giving suppliers the authority to recommend orders to distributors. This method enhances the performance of the supply chain by combining data from the seller and the supplier.

Suppliers may overcome supply & demand difficulties while satisfying customer expectations, keeping competitive, and maintaining margins with the help of the insights that a VMI solution offers. Item stratification, which emphasizes fast-moving products while maintaining the ideal balance of slow-moving items to preserve a broad product catalog, is another VMI feature to boost your performance.

1. Improved Efficiency

Having too much inventory can be expensive and take up valuable shelf space. Conversely, too little stock might lose potential sales and delay customer orders. Finding the right inventory balance is vital for your budget, shelf space, and client satisfaction. A VMI system can handle procurement by automatically generating purchase orders, helping prevent data entry errors.

2. Lower Operating Costs

VMI is unique in enabling companies to save money throughout the supply chain. Since the seller maintains stock, it cuts down on the time spent on inventory planning on the retailer’s end. Additionally, it eliminates the need for excess storage space and helps avoid unnecessary ordering. Lower holding costs result from fewer unused inventories. Retailers frequently don’t even pay for the stock until it is sold. As a result, the company has more cash to use for other needs.

Vendors can cut expenses by managing inventories for many merchants. Schedules become more dependable and organized when vendors oversee inventory shipments.

3. Simpler Processes

You can avoid dealing with multiple vendors by managing your inventory with a VMI partner. There are fewer details to be concerned about when all of that back and forth is eliminated. You can also maintain an inventory delivery schedule that is predictable and dependable.

Ordering too much or too little goods is less likely when working directly with vendors. In addition, suppliers bear the risk of their goods not selling quickly enough because they have control over the inventory.

4. Data Analytics

Your online business can take advantage of reliable and timely stock updates and orders via the ongoing data exchange between retailers and vendors. In contrast to other supply chain management systems, VMI orders inventory more strategically using recent sales as a guide.

Vendors can also combine data analysis from various shops to identify and prepare for regional trends.

5. Stronger Relationships with Suppliers and Clients

VMI is a mutually beneficial partnership between the vendor and the retailer. You can expect the working relationship between the two to be stronger when everything goes according to plan. As a result, the vendor’s long-term business prospects are strengthened, and the retailer’s confidence in their product supply is increased.

A thorough plan is also necessary for starting vendor managed inventory. Businesses tend to be more loyal to trusted VMI vendors to avoid repetitive extensive onboarding procedures.

Suppliers with stronger ties will gain a competitive edge as they can support on-time delivery and provide better customer service. Vendors may offer loyalty programs or bulk discounts to attract customer sales further.

Vendor managed inventory lowers costs and risks and improves stock level forecasting and management. More importantly, it fosters closer ties between suppliers and merchants and reduces the risk of human error.

For companies searching for a more affordable solution to manage their inventory, vendor managed inventory can be a great choice. You may choose the best option for your business by weighing vendor-managed inventory’s advantages and disadvantages. Remember to do your due diligence when researching potential VMI partners.

ZhenHub has all the tools to power your vendor managed inventory integrations. Get access to your inventory levels at any time. Multi-channel integrations make it easy to forecast demand across all your marketplaces. Sign up to experience efficient eCommerce logistics solutions.