Economic Order Quantity: Definition and Formula

Time to read: 6 minutes

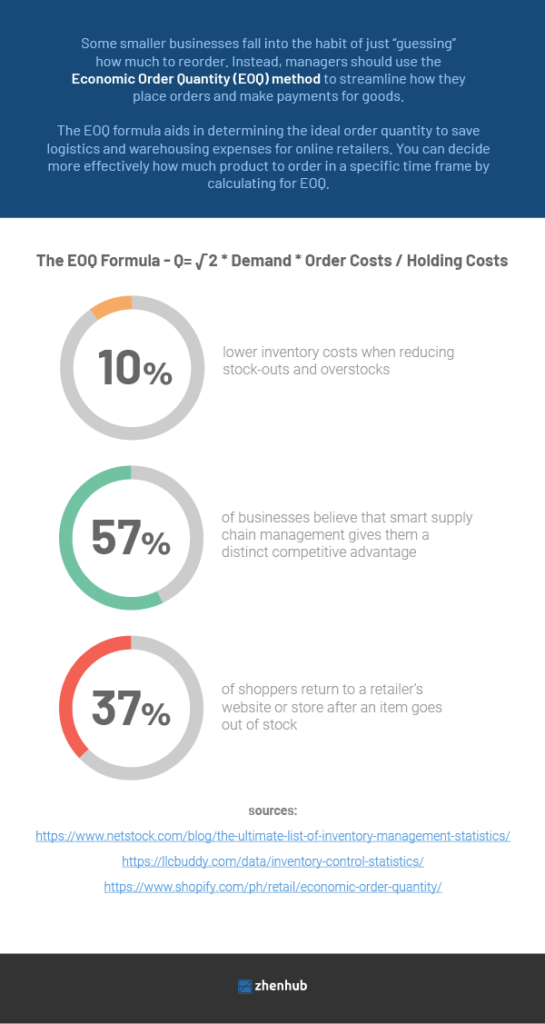

Managers and retailers sometimes have difficulty finding the best amount for stock replenishment for a particular item in daily operations. Order quantity is serious. Ordering fewer things might lead to an out-of-stock situation, while ordering fewer items raises your holding costs. Both are detrimental to any business and ought to be avoided if you want to maintain the viability of your operations.

It’s crucial to place orders in the quantities that most closely match your requirements for any company that purchases and maintains inventory. Economic order quantity (EOQ) enters the picture here.

You can have too much money locked up in inventory and storage costs if your orders are too big. You will only be able to satisfy your client’s needs if you place a large order. Finding the sweet spot where your company makes the perfect order size and maximizes income is easier with the help of EOQ.

Defining Economic Order Quantity

Economic order quantity is a logistics model used to establish optimal inventory levels. It’ll increase inventory, reduce holding costs, and prevent stockouts. On top of that. It will assist retailers in determining the optimal order quantity.

EOQ is also called “optimum lot size,” which is the number of units you should add to inventory with each buy order.

It makes no difference whatever product your company sells. Finding the economic order quantity for any product you buy will impact revenue. Measuring and following the EOQ can benefit any company that controls inventory.

Economic order quantity is a relevant statistic for companies that purchase and maintain inventory for manufacture, resale, internal usage, or other reasons. Businesses that follow EOQ take into account demand for the goods, purchase discounts, and holding costs. That also includes all costs associated with purchasing and delivery.

Calculating Your Economic Order Quantity

Knowing the demand for products, the expenses of placing orders, and the costs of holding or storing the commodities are necessary to determine EOQ. Usually, this data is produced annually.

While there are several ways of calculating your EOQ, a popular formula requires using variables or input. Before we present the formula, let us first understand the major components needed in the formula.

- Demand (D) – the annual volume of items/products needed to meet customers’ or manufacturing needs

- Order Costs (S) – Also known as set-up cost. The cost or price needed to acquire certain individual orders. Includes the cost of shipping and handling.

- Holding Costs (H) – Can also be referred to as carrying costs. The total expenses are tied to storing and holding unsold inventory. This can include warehouse, staff salaries, damages, and opportunity costs.

The EOQ Formula: Q= √2DS / H

For us to fully understand how to get our economic order quantity, let’s use the formula as an example. Suppose you own a shop that sells guitars. In a year, your need to purchase around 25,000 units of electric guitars to meet customer demand. Since you source your guitars from a boutique shop, they charge you about $750 for the order. Storing them in your shop backroom costs you $10 per guitar.

EOQ = √2 X 25,000 X 750/10 = √3,750,000

EOQ = 1,936.49

Once you have your final figure, round up to the nearest whole unit. Therefore, your guitar shop should set the economic order quantity at 1,937 units.

This EOQ formula works on the assumption that your customer demand is constant. Additionally, the computation counts on the ordering and holding costs staying consistent. Because of this, the formula is less effective when considering business events like shifting consumer demand, seasonal variations in inventory costs, and lost sales due to inventory shortages. Businesses might also get inaccurate purchase discounts if they buy larger inventory quantities. Keep this in mind, and be sure to consult historical data. Despite these drawbacks, businesses can still greatly benefit from using the EOQ to improve their inventory management.

Understanding these restrictions and ensuring they apply to your business needs is essential. Due to these limitations, businesses must be cautious when using this specific EOQ methodology. Organizations should combine economic order quantity with other inventory management strategies to guarantee that their inventory is properly maintained.

You can determine the optimal order size to boost profitability for your business when you compute EOQ. You’ll worry less about ordering too much or running out of stock since you are working on accurate data, eliminating guesswork. You can follow the statistics and the number to get the best long-term options for inventory requirements.

But to conduct precise calculations, the necessary data must be available. The EOQ model assumes a constant need for a certain product and that you can supply it immediately.

A lack of accurate, real-time data on holding or order costs will result in incorrect inventory levels, which can soon cause a stockout.

You must estimate demands based on previous demands to decide how much inventory to keep on hand. If you’re utilizing spreadsheets and don’t have any tracking in place, this can take a lot of time. However, inventory management software can compile this data in a few clicks, allowing you to input the correct information into your EOQ calculation.

EOQ can have a substantial effect on your business. Utilizing EOQ can benefit large operations as it increases operational effectiveness, cash flow, and greater profitability for years to come. It’s also great for managing expensive inventories and monitoring high inventory holding costs.

Why Economic Order Quantity is Important

The EOQ formula aims to determine the ideal quantity of product units to order. If accomplished, a business can reduce the cost of purchasing, distributing, and storing units. Businesses with extensive supply chains and high variable costs can also utilize an algorithm in their inventory software to generate EOQ. The EOQ formula can be changed to determine production levels or order intervals.

Economic order quantity is an essential cash flow tool. The equation can assist a business in managing the amount of cash held in the inventory balance. Other than human resources, inventory is often a company’s biggest asset. Thus, these organizations must keep enough of it on hand to meet client demand. If EOQ can reduce the amount of inventory, the money saved can be invested or used for other business needs. You can enjoy profitability in several business areas by maximizing EOQ.

Lower Inventory Costs

Excess goods can contribute to exponentially rising storage costs. Inventory expenses may also increase depending on how you order, what gets damaged, and what products never sell. EOQ can help you decide how much to get over a specific time if you frequently reorder low-velocity products. That way, you can easily manage all your goods in storage without unloading unsold items.

Avoid Stockouts

EOQ can also assist you in determining how much and how frequently you need to place new orders. It’s easier to prevent stockouts without keeping excessive inventory on hand for an extended period. Figuring out how much you need based on how much you sell at a specific time helps with this. Calculating EOQ can help you assess whether ordering in lower quantities is more cost-effective for your company or the opposite.

Greater Operational Efficiency

Overall, knowing your EOQ can help you store and manage your inventory more effectively. The truth is that many e-commerce businesses order more stuff than they need because they have a “gut sense” about how much to order. Utilizing the EOQ formula is a clever, more accurate technique to get the right amount of inventory based on significant cost variables.

You can configure automatic reorder points that will immediately place an order once your inventory levels reach a given threshold. This removes the hassle of manually checking inventory levels to restock products. It’s also easy to integrate or adopt if you invest in inventory management software or work with a third-party logistics (3PL) provider.

There are instances where a sudden rise in demand or problems with a supplier can leave you without enough inventory.

Simply put, safety stock is additional inventory above and beyond anticipated need. Safety stock is frequently utilized during peak shopping times, such as the holidays, and during significant promotions or flash sales. Knowing your EOQ will help you accurately set the optimized amount of safety stock you need.

Economic order quantity is a powerful tool that can assist a business owner or manager in making better inventory decisions. Though it may not be every single business variable, EOQ is an effective tool since it is dynamic and can be periodically reviewed as your company grows. You can always modify the formula and produce a fresh EOQ to reflect the most recent changes in your inventory costs.

Calculating the EOQ can help find a healthy balance for your order and inventory costs, which can be ignored in daily business. The EOQ formula is a helpful tool for intelligent, efficient inventory control. Always practice caution, as it isn’t a one-size fits all solution for all industries and companies.

ZhenHub offers a robust and complete logistics software suite specially designed to optimize eCommerce operations. Get real-time insights on inventory movement and forecast market demand to help with your EOQ calculations. Sign up for free and get access to your digital dashboard.