6 Things to Lookout in an Organized Warehouse

Time to read: 3 minutes

Reading time: 3 min 35 secs

As it turns out, the efficiency of your e-commerce business will depend on how well your warehouse operates. Keeping the warehouse organized will help improve warehouse safety and productivity while also improving the order fulfillment process. Whether you own and operate your own warehouse or you are going to visit the warehouse or fulfillment center that you are looking to use.

So what exactly should you look out for or try to improve if you’re trying to enhance your warehouse organization for better operations?

Efficient layout and design

At the core of every organized warehouse, there is an efficient layout. Optimizing your order fulfillment services will begin with evaluating this warehouse layout. Think about these things;

- Does your warehouse design allow easy access to goods?

- How flexible is the design for goods storage and handling?

- Does the design maximize space and leave workers with enough space to work?

A well-organized warehouse design should make products easily accessible. There should also be a smooth flow of people, product and traffic.

Clean and clutter-free condition

Debris, clutter, and similar things do not have a place in a well-organized warehouse setting.

Aside from posing serious safety and accident risks, they are also a great hindrance to warehouse productivity. There is a lot to benefit in keeping your warehouse clean and clutter-free. It can improve your lead times as well as efficiency. Leaving the warehouse untidy and disorganized can cause obsolete inventory which in turn can increase your cost of inventory.

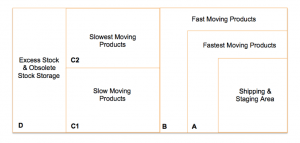

ABC Analysis application

Image Credit: EazyStock

The ABC Analysis is an age-long system of sorting inventory in an organized way. This system groups inventory into three classes based on how well they sell and what it costs to hold them.

This has its roots in the Pareto principle, which holds that about 20% of your stock will account for 80% of your inventory movement. The three classes are;

- A – Best-selling products that don’t use up all warehouse space and cost;

- B – Second-best selling products that often cost a little more to hold; and

- C – The last group of inventory accounting for the bulk of your inventory costs but not frequently sold.

Following this rule, products should be organized and made easily accessible, according to their order of importance from A through to C.

Proper labeling of inventory

Boxes are meant to be labeled at the bottom right corners with all the necessary details.

Aside from helping to improve safety, communication, efficiency, and productivity within the warehouse, proper labeling will help you avoid issues with order fulfillment such as inaccurate deliveries which can ruin a customer’s shopping experience. The details may include SKU, color, size, date, etc.

Effective receiving of inventory

This seems a small task but is one of the most important aspects of inventory management. Issues here can affect the whole of the inventory and order fulfillment processes.

The warehouse should be optimized to ensure warehouse workers have enough space to sort and store the newly received inventory. Along with having the right tools for this, the receiving area should be kept clean, organized, and clutter-free as well.

The newly-received inventory should be checked for quality and stored safely and quickly using the right equipment. You can also consider using an inventory system for real-time tracking. This can help you reduce cases of miscounts, missing inventory, or incorrect shipping.

Cloud-based inventory management

You need a well-organized warehouse for greater efficiency to help you grow your business.

An inventory management system like ZhenHub can help you improve the warehouse organization significantly. This inventory and order management software can help you organize inventory for easy accessibility and quick retrieval. If you’ve been curious about how to organize your warehouse for optimum productivity and efficiency, ZhenHub can help you get started.

If you need assistance with reducing logistics costs, you can reach out to our specialists – hello(a)zhenhub.com or submit an enquiry here.