7 Steps to Master Cold Chain Management

Time to read: 6 minutes

Restaurants need their ingredients fresh to serve delicious dishes. Vaccines have to be chilled for them to work effectively. Nobody wants to receive a bouquet of wilted flowers. These items, from food, vaccinations, fresh flowers, and more, have one thing in common. They must be transported chilled to reach you unspoiled or in excellent condition. The idea of cold chain management is essential when dealing with these kinds of goods.

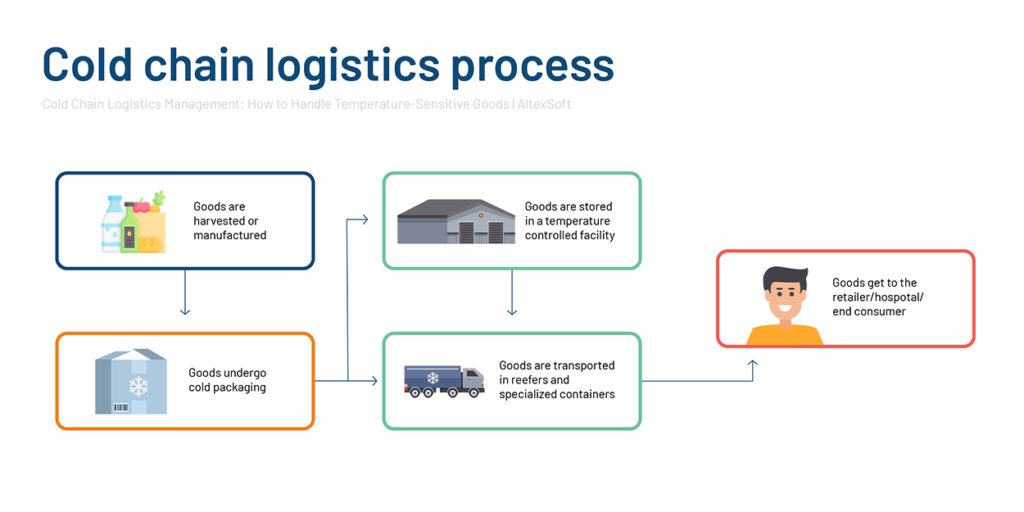

Products that must be kept at low temperatures are managed through the cold chain. It qualifies as a process since it entails carrying out a series of operations to prepare, store, and move products along the cold supply chain. Products not maintained in a cold chain become useless, resulting in product waste. Both the transporter and their client lose money when cold goods spoil.

Managing the entire cold chain, including the products in transit, processed, stored, and displayed, is known as cold chain management.

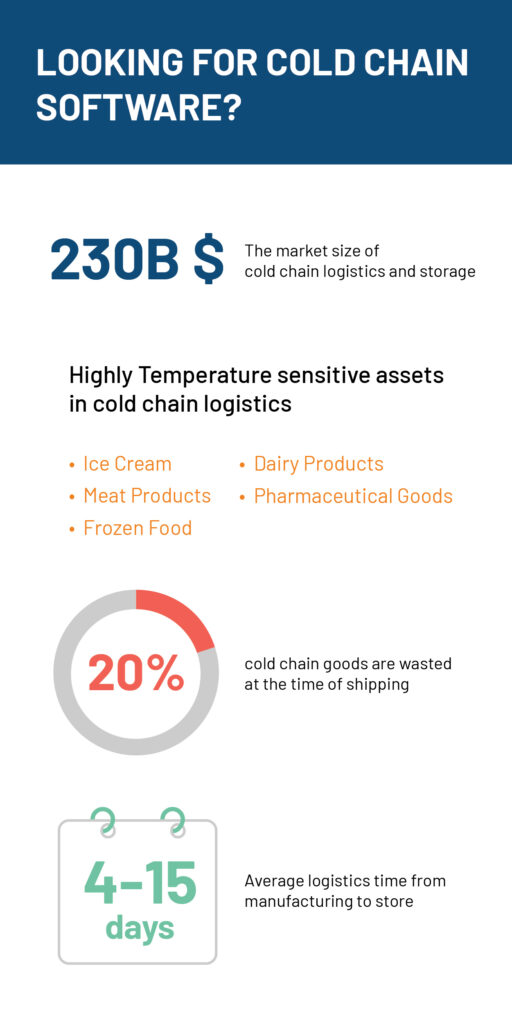

Temperature-sensitive items depend on cold chain management for product effectiveness, product safety, and compliance with regulatory requirements. Pharmaceuticals, vaccines, biologics, lab samples, diagnostic tools, chemicals, food, and drinks require cold chain solutions.

Cold chain management manages temperature ranges and air quality, including carbon dioxide, humidity, and oxygen levels.

The cold chain differs from other supply networks in that product loss nearly invariably follows a failure. It is easy to salvage nonperishable goods. For example, a box of shampoo mistakenly left in a warm warehouse for an extended period can still be sold. The same cannot be said for a pallet of vaccinations or a fruit crate, as these quickly spoil at high temperatures. Each level of cold chain management must be carefully examined to ensure that this chain is efficient and profitable.

The Importance of Cold Chain Management

The safety, integrity, and quality of perishable foods and temperature-sensitive medical goods are protected by cold chain management and logistics. Any reputable grocery would never accept a shipment of frozen fresh organic fruits or chicken delivered at room temperature. Changes in transit temperature can potentially ruin the effectiveness of medications. Strong cold chain logistics also enable supply chain effectiveness and waste reduction. Customer satisfaction significantly increases when time-sensitive products are delivered on schedule, entirely, and to the highest standard.

Cold Chain Logistics Management: How to Handle Temperature-Sensitive Goods | AltexSoft

Effective cold chain management requires strong leadership and collaborative relationships. It also needs a defined cold chain procedure and reliable temperature-tracking devices.

Ensuring the Integrity of Goods and Products

Cold chain management is necessary for certain goods’ integrity, quality, useability, and safety. Utilizing modern thermal packaging, temperature tracking and monitoring, and storage technologies can help online merchants.

Cold chain management and logistics keep the supply chain of essential goods and products running efficiently. Keeping milk cold, ice cream frozen, or vaccinations safe is necessary. Your customers expect to receive orders free of defects, including bruising, discoloration, textural changes, bacterial growth, and worse. Cold chain management is a necessary safety net for your clients’ peace of mind and yours.

Product Security

Through proper cold chain management, you avoid potential delivery disasters. You don’t want your company to be known for selling dangerous goods and products. Effective temperature control and monitoring ensure standards and legal requirements must be met to keep your customers safe and satisfied.

Key components of contemporary cold chain management include continuous monitoring of temperature, humidity levels, air quality, and GPS location. It also provides energy use, delivery and storage conditions, and more.

Increased Efficiency

It is not easy to transport items and cargo over land and sea. Poorly planned delivery can be expensive, time-consuming, and ineffective. Companies can optimize their products’ shipping, delivery, and storage through integrated smart IoT-enabled tracking and monitoring. Cutting-edge technology helps to enhance efficiencies and lower costs.

Less Waste and Loss

Preventing product loss, damage, and waste are some of the biggest challenges every supply chain faces. Thanks to cold chain management, items are traced and monitored at every stage of the cold supply chain. Online retailers must be assured of the security and protection of their goods and products. Businesses can rely on systems and process designs for cold chain management to do this. These comprise sophisticated refrigerants, reefers, cold chain parcel and pallet systems, temperature monitoring, and specially insulated containers.

No company can afford the financial or brand loss due to the cascading effects of destroyed temperature-sensitive products. With the pressure to meet ever-growing customer demand and the threat of market disruptions, you need every advantage.

Superior Customer Service

If you’re running a successful eCommerce business, you’ll have a steady customer base of loyal B2B and B2C clients. However, they expect your goods to be delivered promptly and follow strict safety and quality standards. Logistics and cold chain management provide knowledge and control over the delivery, storage, and distribution processes to satisfy client expectations.

Just in Time (JIT) delivery of thermal packaging materials and a GAP analysis of the cold chain’s best practices ensure a well-organized and cost-effective supply chain.

Compliance with Regulatory Standards

Regulations must be followed to control the secure production, shipping, and storage of temperature-sensitive goods.

Many government agencies in charge of food and drugs are focused on preventing contamination. The standards for in-transit temperature tracking and data monitoring are outlined in their laws. They should also have a governing body that oversees the sanitary transportation of human and animal food.

Government branches that govern health also give comprehensive instructions for managing and maintaining the vaccination cold chain. These include ideal storage conditions, vaccine storage specifications, and temperature control.

If you deal with food and medicines, be aware and current on all your local government’s laws and regulations for transporting goods via the cold chain.

Seven Components of a Successful Cold Chain Management Process

It’s not easy delivering temperature-sensitive goods on schedule and in full. It requires a finely tuned, streamlined procedure that fosters security, effectiveness, and quality from start to finish. And you can think micro. Storage, packaging, tracking, movement, product management, shipping, and, in some circumstances, customs clearance must be included.

Looking for cold chain software? (triare.net)

1. Storage

Insulated containers, vaccine and medical refrigerators, freezers, refrigerants, and cold rooms/chillers are essential to efficient cold storage. Equipment and infrastructure for cold chain storage come first in cold chain management.

2. Packaging

Cold packing is essential for maintaining and monitoring temperature and security when your products leave storage facilities. Cold chain package and pallet systems, refrigerant blocks, gel packs, gel bottles, and insulated containers and envelopes can keep your goods cold. It’ll increase the effectiveness of your shipping and reduce waste, damage, and loss.

3. Tracking

Companies, transporters, and their clients can track and monitor the temperature in real-time using data loggers and temperature indicators. This data is essential for preserving the cold chain and guaranteeing the integrity and quality of the final product.

4. Transportation

Your temperature-sensitive commodities and products are transported worldwide in various methods thanks to the global supply chain. Specialized vehicles like refrigerated vans and reefer containers are required for transportation to keep the cold supply chain in motion.

5. Customs Clearance

Custom documentation is essential in the cold supply chain to ensure your products can be transported and delivered quickly and efficiently. Failure to adhere to customs clearance rules may cause significant delays. Trying to fix customs issues can lead to product loss, quality hazards, and increased delivery, storage, and transportation costs.

6. Product Management

Thanks to unique shipping supplies, your items are transferred and handled securely and safely within the cold chain. Explore using specialized cold parcels and pallets, insulated envelopes and containers, and warehouse best practices with autonomous mobility robots and forklifts.

7. Delivery

A well-tuned and efficient delivery method is essential to delivering temperature-sensitive items and goods to your B2B and B2C consumers. Reviewing documentation, following internal handling best practices, and managing risks should be part of a stringent internal process. As an online retailer, you must secure legal warehousing, storage, and display systems as part of your cold chain management process.

Temperature-sensitive products have different specifications and needs. As every product differs, maintaining its integrity along the cold chain requires specialized management. Shipping providers must adhere to several rules and regulations that industry regulators define for use across the cold chain supply.

Individual shippers must also have internal quality requirements in addition to these rules. Manufacturers of temperature-sensitive goods are outsourcing their cold chain supply to specialized shipping companies that can meet their freight needs. Complying with industry, local, regional, global, and environmental regulations is much easier. Outsourcing helps to estimate lead time more accurately.

ZhenHub has all the tools to support your businesses’ cold chain management initiatives. Keep tabs on where your deliveries are at any time, and gain access to our global network of fulfillment partners. Sign up at our website and get started with our online dashboard.