What is Inventory Optimization?

Time to read: 7 minutes

Every eCommerce merchant wants to expand their business. However, only some take advantage of the one action that almost ensures growth: inventory optimization.

Most direct-to-consumer (DTC) industry merchants concentrate on expanding their brands via advertising and sales. There is a significant possibility to gain more revenue from these strategies due to increased client demand. However, this can only be possible if you first embrace inventory optimization.

Inventory management helps businesses manage customer demand despite disturbances in the global supply chain. Always having what your customers want in stock when they need it is crucial for delivering an outstanding shopping experience.

Inventory optimization is keeping the proper quantity of inventory on hand. It helps to fulfill demand and minimize logistical expenses. Proper inventory counts help businesses avoid frequent problems like stockouts, overstocking, and backorders.

Inventory optimization is a best practice and strategy for eCommerce that guarantees effective stock control management. Many business owners use tools, technology, procedures, and techniques to estimate demand better, track inventory in real time, and optimize storage.

Online merchants will need to take note of several factors. Storage capacities, present inventory levels, supplier lead times, and schedules should all be closely monitored. It should also include seasonal trends and upcoming promotions. These will help dictate the appropriate amount of merchandise available to be fulfilled.

Key Elements of Inventory Optimization

Inventory optimization aims to efficiently order the appropriate number of goods in the ideal amounts to satisfy demand. This is achieved by taking volatility in supply and demand into account. Procurement managers have the task of dynamically modifying inventory characteristics and stock regulations. Proper inventory optimization minimizes the risk of expensive surplus or outdated stock.

How E-Commerce Inventory Management Can Help You Save Money (g2.com)

Managing “leaner” stock levels lowers inventory expenses. This ensures optimal availability by balancing inventory investment limitations and service level (product availability) requirements.

Inventory Levels

Your inventory level is the quantity of items you have in stock at any given time.

A surplus of inventory puts SKUs at risk of becoming dead stock. Holding too many items at once will demand potentially excessive storage costs.

Stockouts resulting from insufficient inventory can turn away consumers and reduce your capacity to make sales. When inventory levels are optimal, you only place orders for what you need.

Inventory Replenishment

When you get additional shipments from your supplier or manufacturer to get your inventory to an ideal level, it is known as stock replenishment.

The replenishment process considers the reorder point for each SKU, your ideal order quantity, and the current inventory on hand. Warehouse managers must consider the lead time for your supplier’s purchase order.

You may use this information to decide what needs to be reordered and when. This way, you can only replenish what is required to fulfill demand.

Storage

Efficient inventory management is essential to any business that deals with tangible products. Managing your inventory to satisfy consumer expectations and make room for business growth is easier with a scalable inventory storage solution.

Remember that storage requirements will differ from company to company depending on several factors: sales volume, product characteristics, and shipping destinations. Developing a strategic approach to storage is a crucial element of inventory optimization.

Demand Forecasting

Demand forecasting is how brands project future consumer demand using historical data and current inventory patterns. Demand and inventory forecasting software are never entirely accurate and will never give you a 100% correct reading.

However, demand predictions (instead of unthinkingly guessing) help companies satisfy consumer demand. It also drastically minimizes their stockout and overstock risks.

Online merchants may use this information to make well-informed decisions about inventory replenishment, minimizing holding and storage expenses.

Six Inventory Optimization Best Practices

Several issues can make inventory optimization challenging. eCommerce businesses constantly have to face shortages of raw materials. It’s also affected by shifts in geopolitics and constraints in the global supply chain.

Thankfully, there are many logistics tools and technologies at your disposal. It’s important to remember that there are many ways to mitigate supply chain issues. Visibility and agility are essential to expertly managing your inventory. Optimization can go a long way in protecting your assets against inflation and shortages.

1. Safety Stock Optimization

Maintaining buffer inventory, or “safety stock,” on hand is a critical component of inventory optimization. This buffer inventory protects the company against supply chain interruptions and demand variations.

Online businesses need to figure out how much safety stock is appropriate to have on hand to get optimal results. Underestimating the required safety stock can result in stockouts and lower customer satisfaction. Keeping excessive amounts of safety stock causes overpaying for carrying expenses. Setting safety stock levels will ensure you have enough products to meet customer demand despite supply chain issues.

2. Streamline Reordering Products

It’s crucial to identify the minimum amount of inventory, including safety stock, that should be kept on hand. But you’ll also need to figure out when to place new orders.

Your reorder point must guarantee that excess capital is not tied up in inventory. Take note of the lead times. It could be the manufacturer’s delivery time, the period it takes your warehouse to receive and store products, and other potential delays. As much as possible, you’ll want your inventory to hold just the right amount of products to keep costs low.

This simple formula may be used to determine reorder points (ROP):

ROP = demand during lead time + safety stock

Even though the calculation is simple, remembering when to place new orders for each product can be difficult and time-consuming. You can automate reordering using an inventory management system that can easily calculate reorder points per item. It can automatically trigger a replenishment order from your supplier once an item hits the reorder threshold. This can save you a lot of time and effort by keeping your inventory well-stocked all the time.

3. Proper Demand Forecasting

Making meaningful supply decisions is possible with the right technology and tools to predict demand. Data-driven planning helps to project overall sales and income for a future period.

Historical order data, which offers insights into sales trends, is the most crucial data for forecasting demand. This data helps you make smarter business decisions, increasing the supply chain’s effectiveness, saving costs, and enhancing customer satisfaction.

Inventory forecasting can also help you determine the best time to hold a sale, when to hire more staff, or when to rent additional storage space.

4. Carry Out Regular Inventory Audits

Track inventory more effectively by conducting regular inventory audits.

Make sure there aren’t any significant disparities in your inventory. Your current financial records and actual inventory levels are compared during an inventory audit.

By making modifications, you may verify that the inventory levels are as precise as possible. Additionally, you can see inventory shrinkage before it becomes an issue (such as missing or damaged products). Holding costs, such as warehouse personnel, storage, inventory shrinkage, and depreciation expenses, should be carefully tracked and calculated.

Manual audits can be time-consuming, especially when managing hundreds and thousands of items. Fortunately, there are ways for eCommerce companies to digitize and automate the process of monitoring inventory. These include using third-party logistics (3PL) fulfillment software or integrating your online store with inventory management software.

5. Use ABC Inventory Management

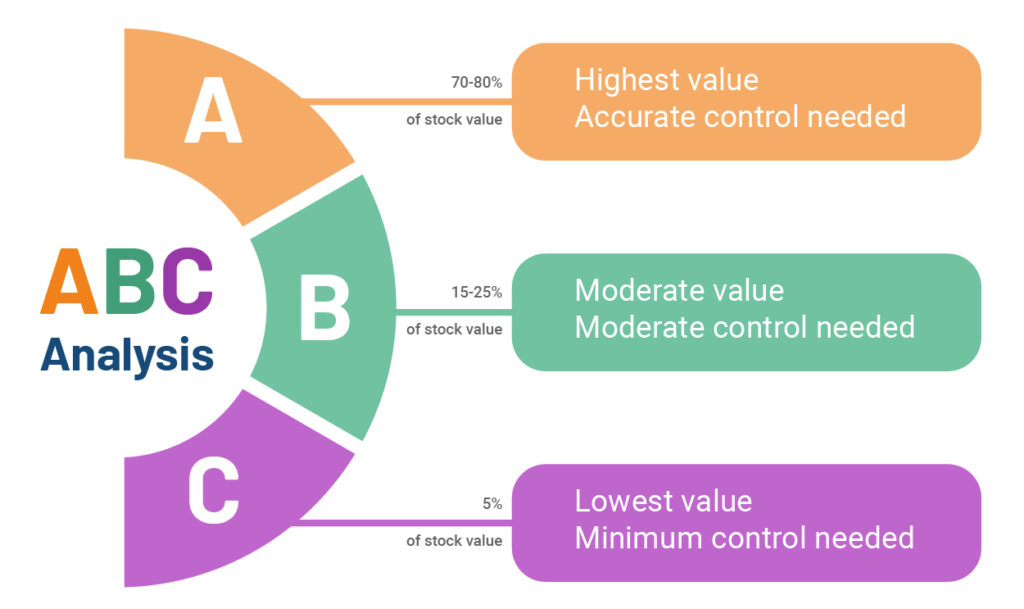

An essential method for inventory optimization is ABC analysis, also known as ABC inventory management.

Using this technique, you may determine the total value of your inventory depending on the item’s consumption value and its importance to your business. The total amount of an item sold during a given period, such as a year, is its annual usage value.

All goods you carry are separated into three “grades”: A, B, and C. Products in grade A are considered the most important and valuable, whereas products in grade C are the least significant. This makes it possible for companies to set inventory priorities. By understanding an item’s value, online merchants confirm that they are carrying products in the appropriate amounts. This all depends on what would benefit them and their clients the most.

Improve your business management with ABC Analysis | Erplain

eCommerce merchants may benefit from ABC analysis in many ways. A deeper understanding of product values helps them prioritize inventory levels and decrease overstocking and understocking. Prioritizing specific items reduces lead times, improving supply chain efficiency and enhancing customer service.

Furthermore, by ensuring that the appropriate products are kept in the proper quantities, ABC analysis can assist in lowering inventory management expenses. Online businesses can increase profitability and maintain industry competitiveness by managing inventory levels.

6. Implement Inventory Management Software

Implementing inventory management software is the easiest way to achieve inventory optimization. You can access a comprehensive view of orders and inventory across all warehouses, sales channels, and customers in one location.

Businesses may select from various inventory management systems to assist them in tracking their inventory and supply chain in real-time. These can be set based on budget and actual business needs.

Not all logistics tools are limited to tracking orders and inventories. Cloud-based and AI-powered tools can automate orders, estimate demand, and recommend new processes. These use current market trends and client behavior to help guide decisions.

Inventory management is essential for every eCommerce store to be competitive. It’s also the foundation for providing a satisfying and unforgettable customer experience. Success in the online retail industry is driven by meaningful inventory optimization.

ZhenHub’s all-in-one digital logistics platform jumpstarts your business’ inventory optimization efforts. From warehousing to inventory management, get complete visibility and control on our online dashboard. Sign up for free at our website for instant access. Contact our fulfillment experts to learn more about which of our solutions fits your business best.