Mitigating Supply Chain Risks through Resilience Strategies

Time to read: 6 minutes

Business success in an interconnected global economy depends on efficient supply chain operations. However, supply networks are vulnerable to disruptions due to their numerous dependencies and factors. Add supply chain risks to the mix, and you have one of the most challenging elements of this networked supply chain.

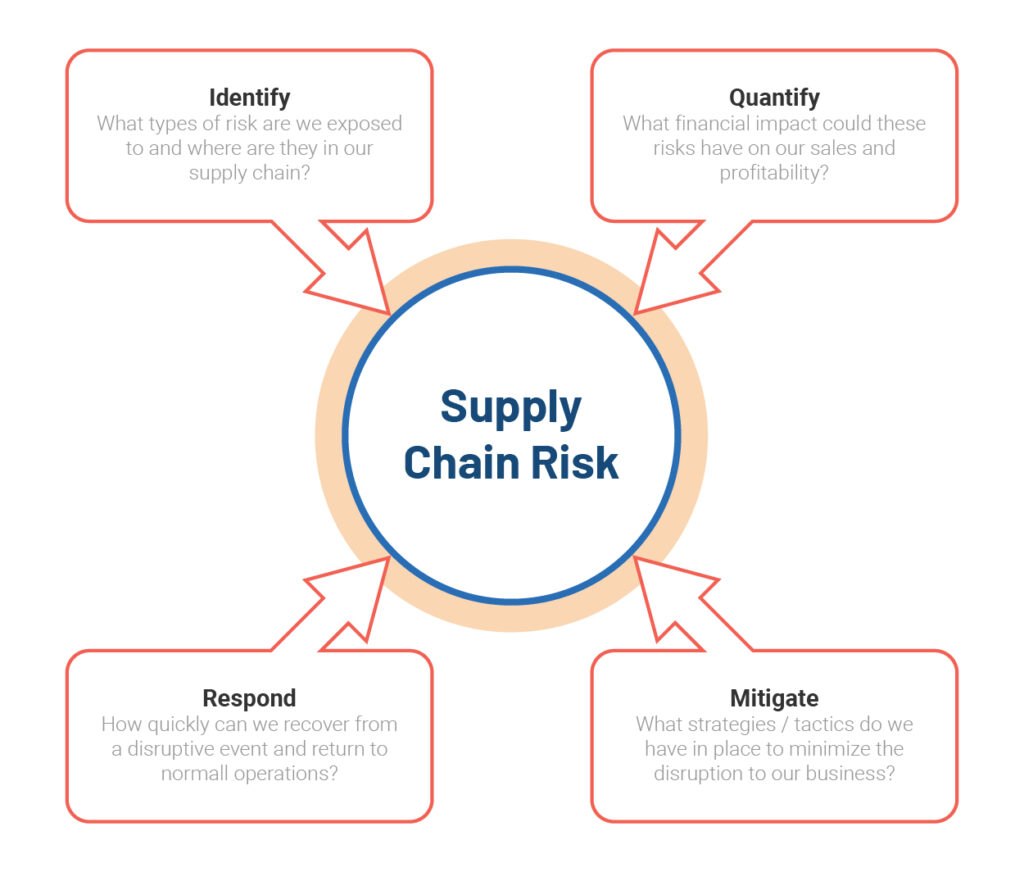

Supply chain risk management is vital to mitigating disruptions as it guarantees company continuity and competitive advantage in your supply chain. It involves identifying, evaluating, and reducing risks. Effective supply chain risk management gives companies of all sizes access to proven tactics that decrease risk and position them for success. Understanding the potential supply chain hazards you may encounter is a helpful first step in creating your risk management plan.

Dealing with supply chain risk means building a more resilient supply chain. Supply chain resilience lets businesses adjust to change and recover from unforeseen or disruptive events within their supply chain network. Natural catastrophes, economic downturns, geopolitical conflicts, and other unanticipated events can impede the movement of products, services, or information.

Agility is vital to a robust supply chain because it allows for prompt responses to disturbances. Moving faster reduces their adverse effects on your operations. However, the most resilient businesses can foresee potential threats and take proactive measures to mitigate them. Business leaders should know the necessity of a well-defined plan to lower risks in their supply chain.

Supply Chain Risks You Need to Know

As mentioned above, supply chain risks can impede the movement of products and services within a supply chain network. Business owners need to be aware of the economy, environment, politics, ethics, and cybersecurity risks. It’s important to distinguish between internal and external threats, as they can interrupt your supply chain.

(28) 6Points to Effectively Control Risks Within Your Supply Chain | LinkedIn

Internal Supply Chain Risks

This refers to any supply chain risk elements that are under your control. Tools like IoT capabilities, robust analytics programs, and supply chain risk assessment software let you identify and track them. To some extent, internal supply chain risks are easier to handle than external ones. Despite that, they are still inevitable.

Operational hazards: These are hazards related to a business’s regular operations. For instance, labor conflicts, IT system failures, or mechanical malfunctions may disrupt the supply chain.

Financial risks: Disruptions that affect the company’s capacity to acquire raw materials or make timely supplier payments. These can be caused by fluctuations in currency rates, cash flow concerns, or difficulties obtaining financing.

Strategic risks: Business actions that might affect the supply chain, such as mergers, acquisitions, or entry into new markets. Poor timing and a lack of data can lead to less-than-desirable results from your planning.

Human resource risks: Staff turnover, strikes, or a lack of training can impact the supply chain’s performance.

Quality risks: A drop in product or raw material quality can result in recalls, reputational brand damage, and financial losses.

External Supply Chain Risks

As the name suggests, these risks come from outside your company. Unfortunately, this means they are more challenging to forecast and usually demand more resources.

Geopolitical risks: Supply chains, particularly those that span many countries, can be severely impacted by political unrest, trade disputes, tariffs, and changing legislation.

Environmental risks: Natural catastrophes like hurricanes, earthquakes, or extreme weather can seriously disrupt production lines, shipping routes, and logistics.

Economic risks: Your supply chain may face serious difficulties due to economic downturns, shifts in demand, or unstable commodity pricing.

Technology risks: Rapid technological breakthroughs may make products and procedures that are currently in use obsolete. Furthermore, cyberattacks or IT system malfunctions can compromise supply chain integrity.

Supplier risks: A supplier’s failures can have a domino impact on the whole supply chain. Operational problems, unstable finances, or other causes can ripple throughout the chain.

To avoid interruptions, you must thoroughly understand the factors that increase your supply chain vulnerabilities. It is in your best interest to be familiar with possible problems before implementing supply chain risk management techniques.

Technologies that offer visibility into your goods as they travel through the supply chain can help you discover possible risk factors. Some solutions, for instance, use prescriptive and predictive analytics to provide a comprehensive, real-time picture of the supply chain. Historical data is interpreted for business insights. Others use APIs to retrieve data and status updates from external sources and third-party suppliers.

Five Resilience Strategies to Deal with Supply Chain Risks

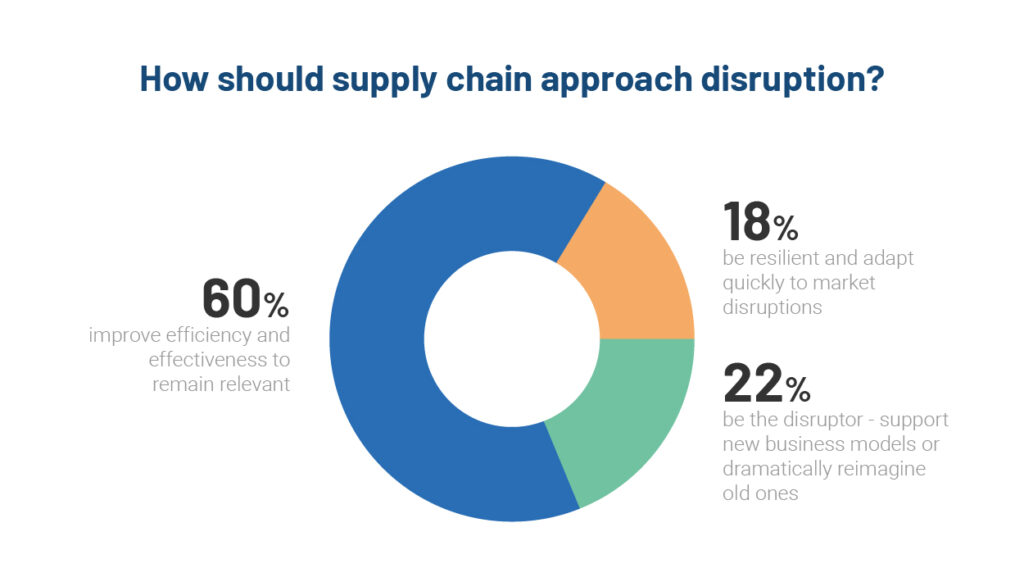

Supply chains aren’t linear, but rather, they are intricate, entwined networks. They consist of manufacturers, distributors, and other associates engaged in creating, holding, and distributing components and merchandise. Proactive action is necessary to maintain competitive advantage and company continuity in the face of impending disruptions.

By implementing thorough risk management plans, companies may improve their ability to foresee, address, and handle supply chain difficulties.

Supply Chain Resilience – The Complete Cin7 Guide | Cin7

1. Supplier diversification

Diversification aims to lower risk. Diversity entails producing in several locations or countries or procuring from various sources. It will lessen the likelihood of relying on one supplier for essential parts or supplies.

Determine other providers and connections beforehand to establish redundancy and protect your purchase. And assess your partners’ dependability frequently.

Using modern AI-based supplier management tools, you may audit your supplier network, evaluate its performance, and discover hazards before problems develop. Monitoring a partner’s performance helps regularly identify persistent issues or drops in productivity, which are potential supply chain risks.

2. Improve supply chain visibility

Gaining more information is helpful. A deeper comprehension of every link in your supply chain will help you identify problems before they become more significant. Understanding your supplier’s financial standing can help you choose potential business partners.

Consider technologies that will enable increased visibility into products and shipments. This will keep your customers informed about delivery schedules. The data you get from real-time updates will allow you to proactively prevent expensive delays and unmet consumer expectations. Tools such as service portals, automatic reporting on inventory levels, and IoT sensors mounted on containers make monitoring easier than ever. This is especially important in the “last mile” of delivery since that is when third-party services may take over.

3. Build a risk-aware company culture

There are two strategies for creating a risk-aware culture that will help mitigate unknown risks. First is educating employees about the impact of supply chain cybersecurity risks. The next is maintaining open lines of communication about the organization’s risk tolerance throughout the supply chain. This foundation will enable stakeholders to make well-informed decisions when interacting with suppliers and customers.

Agility is another key value, motivating all parties to react quickly to emerging hazards and take appropriate action. All stakeholders must be responsible for modifying partner relationships and procedures as needed.

Risk awareness should be a requirement when it comes to supplier due diligence. A risk-aware supply chain can be established by collaborating with vendors with a risk-aware culture, lowering uncertainty.

4. Scenario planning

Scenario planning tools can help companies better prepare for the next disruption. Companies can estimate the financial impact of events such as a major client departing, no orders from two suppliers for three months, or an unexpected spike in demand. Understanding the financial implications of the worst-case, average, and best-case scenarios can influence determining the optimal amount of inventory. Data is used to make decisions rather than educated guesswork.

5. Inventory and capacity buffers

The simplest method of increasing resilience is to increase buffer capacity. This can be for underused production facilities or inventories over safety stock standards. By serving as a safety net, these buffers enable companies to manage supply chain interruptions and uncertainty.

It guarantees that companies can satisfy client requests despite supply chain interruptions. However, keeping excess inventory on hand may be expensive, so be sure to use inventory management software to determine the ideal levels of buffer inventory.

To sum up, supply chain resilience and risk management are critical for companies to maintain their performance and competitiveness. By recognizing problems related to supply chain operations, businesses can create strategies to reduce risks and maintain the resilience of their supply chains.

Online merchants can implement appropriate risk management procedures to lessen supply chain interruptions and ensure their supply chain is robust and productive. Companies also need to cultivate strong bonds with their clients and suppliers to maintain their supply chain’s resilience and dependability.

ZhenHub uses modern logistics technology to help you better manage supply chain risks. Communicate better with your suppliers and track all your moving goods throughout our global network of fulfillment centers. Sign up on our website to take the first step toward a more resilient supply chain. Contact our fulfillment experts for more details.